Institution always strives to protect environment by appropriately handling biomedical waste and strictly adheres to the guidelines from pollution control board Bio-Medical Waste Management Rules & Regulations (BMWM) Amendment Rules, 2018. We have recently implemented OP Data recording online thereby minimising waste. Dental health care leads to generation of wastes such as dental casts/models, extracted teeth, soaked cotton, needles, saliva, mercury, amalgam and various chemicals. Bio-Medical Waste will be collected in color coded bins as per Karnataka State Pollution Control Board (KSPCB) norms and handed over to Common Bio Medical Waste Treatment Facility (CBWTF) “M/s. Anu Autoclave & Incin. Services”.

Solid waste management:

Solid wastes are infectious waste, recyclable plastics, glassware, sharps, dental casts / models, extracted teeth etc. Organic portion of the waste will be treated in Organic Converter and Sewage Treatment Plant (STP). Sludge will be dried and used as fertilizer for gardening. Inorganic portion of the waste will be collected in color coded bins and handed over to waste recyclers.

Liquid waste management:

The liquid waste generated from the hospital activities includes domestic effluent and liquid bio-medical waste. The liquid waste will be segregated, disinfected with 1% Sodium hypochlorite solution and then discharged into STP for further treatment. The treated water is been used for gardening and toilet flushes.

Biomedical Waste Management:

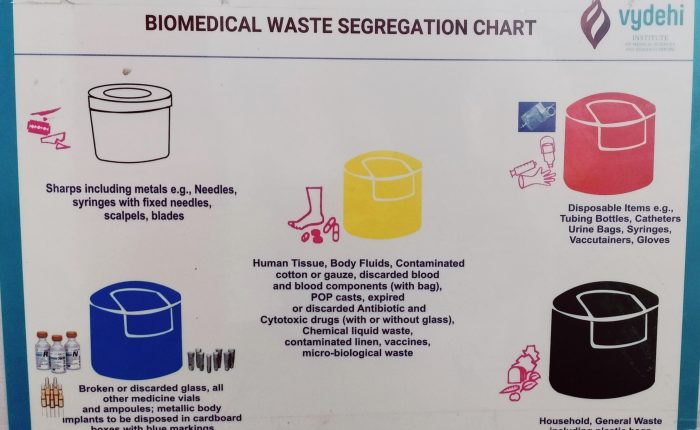

Biomedical wastes are segregated and disposed into colour coded bags red, blue, yellow, green and

puncture proof cans. It is then double bagged and tightly tied and labelled with a biohazard symbol and then handed over to “M/s. Anu Autoclave & Incin. Services.” Color coded bags will be subjected to treatment as per KSPCB norms. General waste would be handed over to to BBMP for further disinfection.

E-waste management:

Institution focuses on minimal generation of e-waste as some electronic devices contain materials that are hazardous. Improperly disposed photocopiers, electric lamps, fax machines and computers may leach lead and other substances into soil and groundwater. If any of the electronic devices or products is found to be non-functional the in-house Biomedical Engineers will perform functional check. After they provide Beyond Economic Repair Certificate these electronic products are then termed as scrap and handed over to e-waste recyclers who possess E-waste certificate from KSPCB.

Waste recycling system:

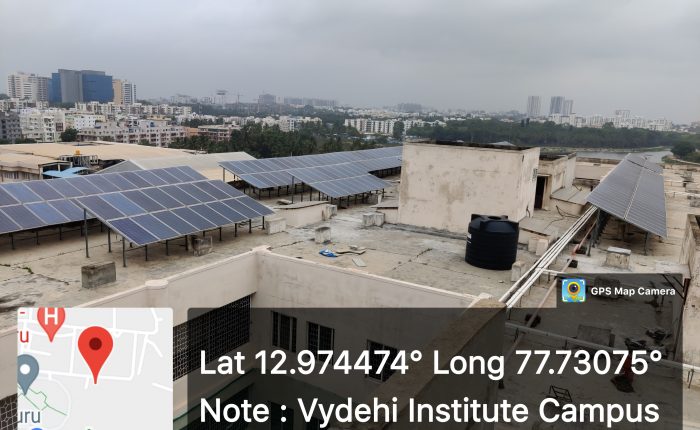

The waste water generated from the hospital activities is being treated in STP. Physical, chemical, and biological procedures are applied to eliminate impurities and yield treated waste water that is harmless for discharge into the environment. The treated water is recycled for toilet flushing and gardening.

Hazardous chemicals and radioactive waste management:

Used cold sterilizer (2% glutaraldehyde) and Developer solution are subjected to treatment in the STP. Fixer solution is subjected to silver reclamation/recovery unit and Lead foil is recycled by scrap dealer. Formalin is neutralized and subjected to treatment in STP. Xylene is kept in a non-chlorinated waste container for disposal. Automatic Blood pressure monitoring device is used to eradicate the usage of mercury. Personal Monitoring Device a radiation sensor is used to measure the amount of hazardous X-ray exposures in an indicated time